Fretting induced fracture of coupling driven shafts james s. Of shaft of greater length, it becomes necessary to join two or more shafts by means of coupling.

Tail Rotor Drive Shaft Coupling Failure - Rotorcraft Engineering - Eng-tips

Parallel offset ß°1 ß°2 a b driving and driven shaft of your equipment must be parallel to within ±1°.

Drive shaft coupling failure. Analysis of the flexible coupling failure established that fatigue cracking in the flexplate arm at the bolted joint between the flexplate and main rotor gearbox yoke Tail rotor drive shaft coupling failure. Here you can see teeths of coupling are damaged/wear in a specific regular pattern.

Investigation methods included visual examination, optical and scanning electron microscope analysis, chemical analysis of the material and mechanical tests. The shaft of a conveyor belt drive pulley failed in service. You need any issues that prevent you from driving the car correctly addressed right away for safe driving and continued use of the vehicle.

There are many possible causes for an abnormal noise in the drive shaft. The drive shaft was implemented. It is important to diagnose and fix drive shaft problems early because no car can shift from idle to drive without a functioning drive shaft.

The flanges are fitted with 6 bolts on 125 mm bolt circle. The drive shaft to be displaced laterally and the flexible coupling to flail against the surrounding structure. An early and common symptom of a failing drive shaft is an intense vibration coming from underneath the vehicle.

I removed the bolts and gave it a couple of light taps with a mallet, and tried separating them with a flathead screwdriver, but i can't get them separated. The failure of both couplings occurred on the middle roll between the first stand and the gearbox, roll side, fig. The shaft couplings will also need to be undone for the same reason.

One possible cause is a weak boat transom or boat bottom that tends to flex under strain. The most likely cause of the failure is due to the interaction between torsional vibration and the operation of the governor. The shafts that are connected by coupling should be easy enough to assemble and dismantle for the purpose of repair and alterations.

Angle is ½° to 1°, unless the driver or driven produces torque spikes, such as a reciprocating engine or compressor, then an operating angle of 2° to 3° is desirable. There are many symptoms of drive shaft problems, including car noises, difficulty turning the car and shaking of the car. In such a case, the vehicle can no longer be propelled, and the.

Experiencing a significant shudder when accelerating from low speed or a stopped position, it can be another sign of failing driveshaft components. If the drive shaft's universal joint revolves very fast or cannot revolve, then there is an issue with your shaft. Fyi, you lost the shaft out of the coupling due to misalignment which caused the shaft to coupling fit failure due to.

Only area of approx 5mm is damaged in this coupling and on the other end splines teeths are of 5mm approx length. The failure criteria (ref failure theories for the shaft depends on the material selection. The gearbox is unbolted and supported as it is moved clear and can then be lifted clear for inspection on a bench.

At high loads and speed, the. The drive shaft coupler is stuck to the transmission coupler. An offset a, of 1/8 to 3/16 per

If the cushioned plate option is followed, this is not necessary. Cars with failing drive shafts may emit a variety of noises, such as loud clunking. The highest vibration level dropped from 24 mm/s pk at the gearbox horizontal measurement locationnear the input shaft to 7.8 mm/s pk after change to a flexible coupling.

This can cause engine misalignment, which usually leads to coupler failure. An investigation was performed in order to determine the failure root cause and contribution factors. Laub, senior engineer carrier corporation, syracuse, new york abstract failures of externally driven compressor crank shafts may sometimes be due to fretting induced fatigue cracks.

For the safe stresses mentioned below, calculate 1. This is because, with the passage of time, the bearing seal cap can rust. Two 35 mm shafts are connected by a flanged coupling.

This drive shaft has allowed play of 5mm in axial direction. Mechanical components directly mounted on shafts include gears, couplings, pulleys, cams, sprockets,links and flywheels. If the shaft is to be removed, the gearbox oil will need to be drained first.

Pdf Analysis Of Ship Shaft Line Coupling Bolts Failure

Failure And Fracture Analysis Of Austenitic Stainless Steel Marine Propeller Shaft Springerlink

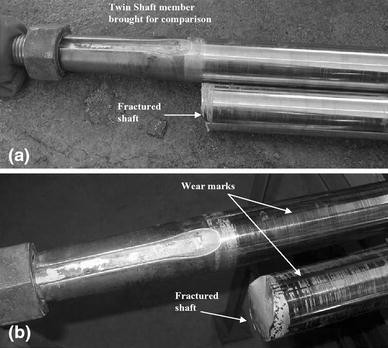

Failure Analysis Of Conveyor Pulley Shaft - Sciencedirect

Undamaged Driveshaft Failure Download Scientific Diagram

Drive Shaft Components Machine Service Inc

6 Symptoms Of A Bad Driveshaft And Replacement Cost In 2021

Failure Analysis Of Conveyor Pulley Shaft - Sciencedirect

12 Reasons For Coupling Failure And How To Avoid Them - Insight - Acorn Industrial Services Ltd

Pdf Failure Analysis Of A Dynamometer Drive Shaft Coupled To An Engine Semantic Scholar

Transmission Driveshaft Coupling Cracked Ford Transit Usa Forum

Ford Transit Driveshaft Flexible Coupling Lawsuit Filed Carcomplaintscom

Failed Pulley Shaft Sample B Download Scientific Diagram

Tail Rotor Drive Shaft Coupling Failure - Rotorcraft Engineering - Eng-tips

Avoiding Coupling Failure - Considerations In Design Selection Ruland Ruland

Coupling - Wikiwand

Flexible Shaft Couplings For High Temperature Applications

Tail Rotor Drive Shaft Coupling Failure - Rotorcraft Engineering - Eng-tips

Avoiding Coupling Failure - Considerations In Design Selection Ruland Ruland

Pdf Common Failures Of Ship Propulsion Shafts Semantic Scholar

Drive Shaft Coupling Failure. There are any Drive Shaft Coupling Failure in here.